The AR-15 pattern rifle has several design features that have helped it become popular for varmint shooting. First is the detachable magazine, which is usually best in 10- or 20-round capacity versions, as they don't protrude so far down to cause interference with the rifle being rested on sandbags . When sitting on the edge of a heavily populated prairie dog town, the high capacity and quick reloading feature is appreciated and can translate into more hits at the end of the day.

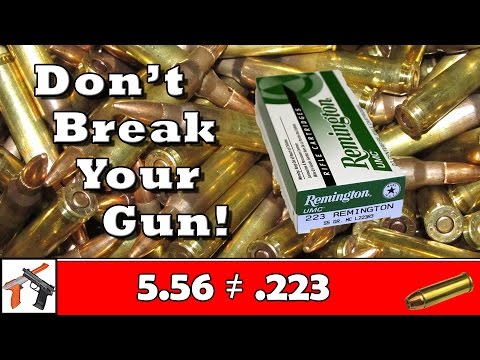

Furthermore, the AR-15 stock is essentially directly behind the barrel , resulting in much of the recoil being directed backward with little muzzle rise. Varmint shooters appreciate these features, as it allows viewing bullet impact through the scope. If a varmint is missed, compensation can be made immediately with a quick follow-up shot without moving from the rest or shooting position. With the correct combination of ammunition, bullet style and weight, barrel twist, along with a quality rifle, accuracy is often under .5 inch at 100 yards. While the 5.56 mm and .223 cartridges are very similar, they are not identical. Military cases are made from thicker brass than commercial cases, which reduces the powder capacity , and the NATO specification allows a higher chamber pressure.

Test barrels made for 5.56mm NATO measure chamber pressure at the case mouth, as opposed to the SAAMI location. This difference accounts for upwards of 20,000+ psi difference in pressure measurements. The 5.56 mm chambering, known as a NATO or mil-spec chambers, have a longer leade, which is the distance between the mouth of the cartridge and the point at which the rifling engages the bullet.

The .223 chambering, known as the "SAAMI chamber", is allowed to have a shorter leade, and is only required to be proof tested to the lower SAAMI chamber pressure. To address these issues, various proprietary chambers exist, such as the Wylde chamber or the Armalite chamber, which are designed to handle both 5.56 mm and .223 equally well. In 1961, marksmanship testing compared the AR-15 and M-14; 43% of ArmaLite AR-15 shooters achieved Expert, while only 22% of M-14 rifle shooters did. In July 1962, operational testing ended with a recommendation for adoption of the ArmaLite AR-15 rifle chambered in 223 Remington.

In September 1963, the 223 Remington cartridge was officially accepted and named "Cartridge, 5.56 mm ball, M193". The following year, the ArmaLite AR-15 was adopted by the United States Army as the M16 rifle and it would later become the standard U.S. military rifle. The specification included a Remington-designed bullet and the use of IMR4475 powder, which resulted in a muzzle velocity of 3,250 ft/s and a chamber pressure of 52,000 psi. Chambers cut to .223 Remington specifications have a shorter leade area as well as slightly shorter headspace dimensions compared to 5.56 mm "military" chamber specs, which contributes to the pressure issues. Twist rates as a ratio – smaller ratios as more rotationsScience aside, your rifle's barrel length and twist rate makes certain rounds give the best performance. While you might hear that the bullet weight dictates the twist rate , this is not entirely true – but usually true enough for practical purposes.

From a scientific point of view, length of the bullet has more to do with the best twist rate than weight alone. The weight measurement usually still works in our case because heavier bullets are often simply made to be slightly longer in length to achieve the extra weight. So weight is a pretty good practical measure in most cases.

Another common mistake is saying that the weight in grains has to do with the amount of powder in the round. The reality is a heavier grain round might have more powder or it might not. Early Armalite and later Colt AR-15/M16 rifles featured a one-in-12-inch twist rifling with some reports indicating that a one-in-14 twist was also tested and used. I had one during the early 1980s, but they are not especially common. Period military ammunition, known as M193 ball, contained a 55-grain FMJ boat-tail with a muzzle speed of 3,250 fps.

By 1980, FN designed a 62-grain bullet for the 5.56 NATO that featured a lead core with an FMJ in boat-tail form, but it had a steel penetrator tip and was rated at 3,100 fps. This required a faster-twist rifling, with the U.S. military changing in 1984 to one turn in 7 inches to accommodate the newly adopted M grain ball load. Today, however, military ammunition continues to evolve with more specialized bullet weights for purposes that include close-quarters combat, optimized long-range loads and long-range target competitions.

As a result, manufacturers report government contracts for M16 rifles with twist rates that also include one in 9 and one in 8 inches to better optimize accuracy with specified bullets at defined distances. Manufacturers offer the same twist rates for rifles sold to the civilian market, but select companies still offer twists of one in 12 and one in 6.5 inches. The two cartridges are dimensionally similar but are only partially interchangeable.

For example, the .223 was loaded to a maximum average pressure of 52,000 CUP , and pressures are measured in the case body. The 5.56 is currently loaded to 58,500 psi, with pressures being measured just forward of the case mouth in the chamber. This different pressure measurement method translates to approximately 62,000 psi chamber pressure. The chamber throat of the 5.56 is also longer than the .223.

Let's take a look at the recoil energy that is generated from our ten selected rounds and see if this trend holds up or if we see a little more variability. This data was generated using each rounds bullet weight, muzzle velocity, gun weight , and the powder charge. For the powder charge, we averaged several common powder loads from Nosler's load data and kept that charge constant for each round of the same cartridge. These numbers might fluctuate slightly depending on the actual powder charge used by the manufacturer, but the trends between the cartridges should remain . This twist rate was used on early AR-15 rifles, and custom builders can still make an upper to this specification.

It generally stabilizes bullets ranging from 35 to 55 grains but especially thrives with virtually all cup-and-core 45- to 53-grain weights. These bullets have become particularly popular with varmint shooters for their ability to reach high velocity and give explosive performance at common prairie dog shooting distances of 150 to 300 yards. Interestingly, many .223 Remington bolt-action sporting rifles that have earned an outstanding reputation for accuracy with 50- to 53-grain bullets are fitted with this twist rate. The comparatively slow bullet rotational speed permits its use with many of the highly frangible varmint bullets without their disintegration in midflight. Several of the powder manufactures list 5.56 loads seperate from 223, within their on line manuals.

With the common 55gr and 62gr bullets the COL remains the same, this is because the bullet canlures for crimping is the determineing factor. With the huge variety of mostly heavier bullets without a canlure the additional length of the 5.56 chamber can be utilized. You're unlikely to find a 1-in-14 barrel on any AR-15 produced in recent years, but they do exist and you may encounter them on a bolt action rifle on occasion. This is the least-versatile twist rate you'll see in the 5.56x45mm/.223 Remington chambering. Although 1-in-14 barrels can stabilize 55-grain bullets used by the original M16, it's really better suited for bullets up to 50- and 52-grains—most of which fall into the varmint and target category.

If achieving maximum velocity with light bullets is your goal, this may fit your needs — Winchester's 45-grain JHP load is a screamer at 3,600 feet per second. The .223 Remington performed well enough for the military in the 60's and 70's. This meant "suping" up the old round with higher pressure, resulting in greater velocity with a heavier bullet.

In the late 1970s, FN Herstal introduced a new version of the .223 Remington called the 5.56 NATO. It consisted of the SS109, SS110, and SS111 cartridges. The SS109 weighed 62 grains compared to Remington's 55-grain bullet. It used a steel core to provide armor penetration at 600 meters. This round would become the popular M855 "Green Tip" in use today. This heavier bullet generates more pressure and uses a different chamber than .223.

This is why it is not always safe to cross-load 5.56 NATO and .223 Remington in a single AR-15. Let's take a closer look at ballistic data and specification of the two rounds, then we'll answer some common questions. On the other hand, the .223 cartridge can be safely used in any rifle chambered for the 5.56.

Keep in mind, however, that .223 cartridges are not generally loaded with a mil-spec primer and neither are they crimped in place. Depending on how a given chamber is cut – leade angle, etc. – some rifles fail to shoot .223 ammunition to its full potential. For short-range trajectory, we are going to compare our selected rounds out to a distance of 300 yards with the test firearms zeroed in at 100 yards. Data was generated by compiling the numbers from the manufacturer or by a ballistics calculator. With the ballistics calculator, we determined the short range trajectory by using each rounds bullet weight, muzzle velocity, and ballistic coefficient .

By observation, 5.56×45mm NATO ammunition is not as accurate as 223 Remington in many of the AR type rifles extant, even with the same bullet weight. It was designed to increase the accuracy of 5.56×45mm NATO ammunition to that of 223 Remington. Other companies also have chamber designs that increase 5.56×45mm NATO accuracy. Since all AR-15 chambers and 5.56 NATO cartridges have variances in their design, you can never be certain that you're operating at truly safe chamber pressure limits.

Even if your .223 gun seems safe and accurate after firing a few dozen NATO rounds down the tube, the small increase in pressure could climb over the advertised rating of 62,000 PSI. Over time, this would result in added wear-and-tear on your barrel/chamber, receiver, and rifling. That means changing your barrel sooner than you should have to. What I am saying is that I have had perfectly fine, even outstanding, accuracy shooting .223 loads, in both 223 and 5.56 brass, in 5.56 spec chambers.

The 7-inch twist has become a standard for long-range competition and target work and is most often used in conjunction with 60- to 80-grain bullets. These loads exceed industry cartridge guidelines and are too long to function in magazines without the above modification, or they must be fired in the single-shot mode only. Clearly this approach is competition driven and impractical for defense or hunting applications.

From our experience and research, the 7.62x39mm offers a lot more options when it comes to hunting more medium sized game. The increase in bullet energy for these rounds within 100 yards is much better suited for medium sized game. For shots within 100 yards, you have a fair shot at good bullet placement, and with the stopping power of the heavier bullets, you should be able to make a clean kill. These same regions also make it a popular cartridge for close quarters combat. If you pair the correct bullet design, you can easily punch through cover with this cartridge with power to spare.

The 223 Remington and 5.56×45mm NATO barrel chamberings are not the same. While the cartridges are identical other than powder load, bullet weight, and chamber pressure, a significant difference is in barrel of the rifle to be used, not in the cartridge. The 5.56×45mm NATO chambers are dimensionally larger in certain critical areas than 223 Remington chambers. As the chambers differ accordingly the head space gauges used for the two chamberings differ. The external dimensional specifications of 223 Remington and 5.56×45mm NATO brass cases are nearly identical.

When hand-loaded, care is taken to look for pressure signs as 5.56×45mm NATO cases may produce higher pressures with the same type of powder and bullet as compared to 223 Remington cases. Sierra provides separate loading sections for 223 Remington and 5.56×45mm NATO and also recommends different loads for bolt-action rifles as compared to semiautomatic rifles. Shooting a 5.56 NATO cartridge out of an AR-15 with a .223 chamber will result in a greater pressure than the chamber is designed for. Thisover-pressurizationis why many shooters say it's not safe to shoot 5.56 in a .223 gun.

It's not just more powder in the cartridge causing the higher chamber pressure with 5.56 loads in .223 guns. It was designed to be able to shoot both standard 5.56 NATO military ammunition and heavy bullet (75-77 grain) match rounds more accurately than a standard 5.56 NATO chamber. Bill Wylde did this by changing the leade, or the chamber throat so it was tighter than a NATO chamber, but still had enough room to safely accommodate longer bullets.

The .223 is a relatively short cartridge designed for more compact rifles. It is shown here with the larger 6.5 Creedmoor.As a result, M16s got generous chambers. Bolt-action rifles enjoyed tighter tolerances, shorter bullet jump and slower 1-in-12 rifling for popular 40- to 55-gr. But, today's AR's in the civilian market have proven to be extremely capable of impressive accuracy as well. Determining proper twist is a factor of bore diameter, velocity, bullet weight and even bullet construction.

It is not safe to shoot "5.56" "5.56 NATO" or "5.56x45mm" ("5.56") ammunition in a firearm with barrel marked as being chambered in 223 Remington for a number of reasons. This can result in serious injury or death to the user and/or bystanders, as well as damage to the firearm. These rounds are designed with a larger size than the .223 rounds. However, they are incredibly lightweight and travel at ultrafast speed to reach high distances.

These rounds are arguably the best in the 5.56 NATO rounds categories. They are also ideal for many applications, including hunting, target practice, and tactical situations. Importantly, their reliability is also on another level and delivers enviable stopping power. The bullets are powerful and reach a muzzle velocity of 3100fps from a 24-inch barrel. Many gun experts agree it is one of the best ammo for self-defense. Additionally, manufactured 5.56 rounds are made for the longer leade and, therefore, may have the bullet seated differently.

If the bullet from a 5.56 makes contact with the rifling in a chamber designed for a .223 Remington prior to being fired, this too can cause unwanted pressure increases. So what bullets and twist rates are correct for varminting or taking that long-range coyote? First, bullets of the same weight can vary dramatically in length, bearing surface and ballistic coefficient and may require a different twist rate for perfect stabilization. In extreme instances, bullets can become damaged in a poor quality bore and fragment upon exiting.

Reasons for these twist rates have included changes in military ammunition in an effort to improve overall performance, long-range competition and advancements to hunting and varmint bullets. Also, the throat or leade is longer in the 5.56x45 mm chamber. You should not shoot 5.56x45 mm NATO out of a rifle that is chambered in .223 Rem. Ammunition will not reliably cycle through some AR-style .223 Rem. As a matter of fact, I have not encountered any difficulty with current .223 Rem. Comparing averages, we get a 1% difference in muzzle velocity between the two chambers.

The graph above shows amazing consistently between each trial run, too. This indicates with no doubt that chamber pressures are just about exact in both guns. The result is a gun that can safely and accurately chamber both 5.56 NATO and .223 Remington, without sacrificing the performance of either. The real difference between 5.56 and .223 isn't the cartridges, but the chambers and barrels of the guns firing these two cartridges. Remember those reliability issues the M16 suffered in Vietnam? When the rifle got dirty and gunked up, tight tolerances made chambering rounds and cycling the weapon difficult.